Enhanced photocatalytic performance in reduced porous titanium dioxide for hydrogen production

Published 21 October, 2024

Photocatalytic water splitting is a promising technology for hydrogen production. A key challenge for photocatalytic hydrogen generation is to find a suitable catalyst that can absorb sunlight efficiently for water splitting.

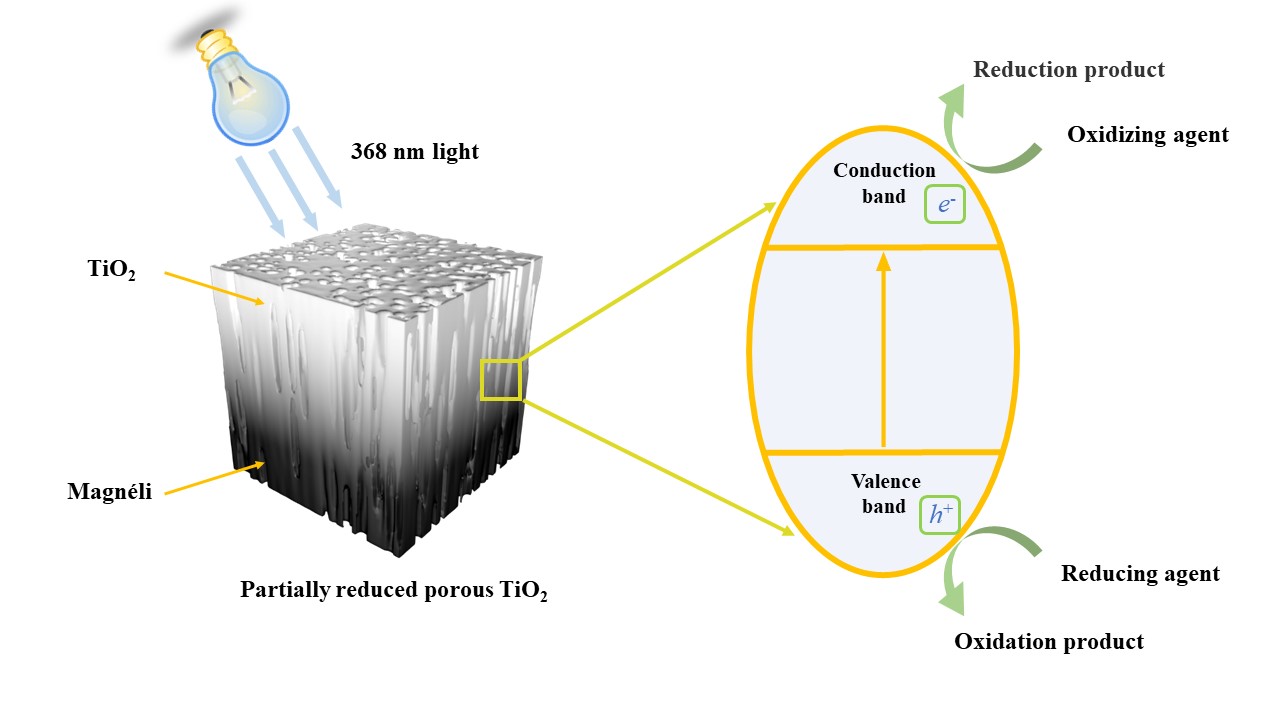

To that end, titanium dioxide (TiO2) has been widely used as a photo-anode in the field of photo-electro-chemical (PEC) water splitting due to its chemical stability, nontoxicity, weather resistance and low cost. Nonetheless, it remains a difficulty for TiO2 exposed to ultraviolet radiation to achieve water splitting in the absence of a photosensitizer. Moreover, the poor charge separation and slow surface reaction kinetics of TiO2 resulted in unsatisfactory water splitting. Consequently, much effort has been undertaken to improve the photocatalytic performance of TiO2 via elemental doping modification and the introduction of a heterojunction structure.

In a study published in the KeAi journal Advanced Powder Materials, a team of researchers from Central South University in Changsha, China, proposed a partially reduced porous TiO2 with a graded reduction profile as a new type of photo-electrode for photocatalytic applications.

“We produced pure porous TiO2 by freeze casting. A porous structure is considered as a feasible strategy to increase the density of highly active sites and facilitate the diffusion of reactants and products,” shares the study’s corresponding author Yan Zhang. “After carbon-thermal reduction, the phase, microstructure, conductivity and the relationship between the photocurrent density and potential of resulting partially reduced porous TiO2 were investigated systematically.”

The researchers found that oxygen vacancy enhanced the AC conductivity of partially reduced TiO2, which exhibited a conductivity 12 orders of magnitude higher than that of the pure TiO2. In addition, the photocurrent density of partially porous reduced TiO2 was 9.14 mA/cm2, and the maximum value in IPCE (%) was 48 times higher than that of pure porous TiO2.

“Our strategy entails increasing the surface area and inducing oxygen vacancies, sufficient to form a kind of electrode material with higher conductivity, thus improving electron transfer efficiency,” adds Zhang. “Furthermore, the Magnéli phase exhibits higher photoelectric conversion efficiency, which bodes well for photocatalytic applications.”

Contact author: Yan Zhang (yanzhangcsu@csu.edu.cn). State Key Laboratory of Powder Metallurgy, Central South University, Changsha, 410083, China

Funder: We would like to acknowledge the Key Research and Development Project of Hunan Province, China (No. 2020WK2004), Hundred Youth Talents Program of Hunan, China, Overseas Talent Introduction Project of China, the Academy of Medical Sciences GCRF Fund, China (GCRFNGR2-10059) and The Leverhulme Trust (RGP-2018-290) for their support.

Conflict of interest: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

See the article: by Hanyu Gong, et al. Improved photocatalytic performance of gradient reduced TiO₂ ceramics with aligned pore channels. Advanced Powder Materials, Volume 1, Issue 3, 2022, pages 100025. https://doi.org/10.1016/j.apmate.2021.11.011