Harnessing Complementary Advantages for Optimal Microbial Control Techniques for Prepared Dishes

Published 28 June, 2024

Prepared dishes are in high demand in Europe, North America, and Asia due to their convenience. Prepared dishes include industrially produced traditional dishes that belong to the category of finished products and can be eaten either directly or after heating, such as Kung Pao Chicken, Shredded Pork with Fish, Mapo Tofu, Korean Bibimbap. In particular, China is the largest contributor to the industry, with more than 70,000 prepared dishes companies in the country. With strong support from the government, the scale of China’s prepared dishes market has grown steadily over the past three years, reaching approximately USD58 billion in 2022, representing a year-on-year growth of 21.3 %. It is projected that by 2026, China’s prepared dishes industry will expand into a trillion-dollar market.

Microorganism has become an important factor in the safety of prepared dishes. The proliferation of spoilage microorganisms has been detrimental to the quality of prepared dishes, leading to wastage of resources and economic losses. Pathogenic microorganisms, including Escherichia coli, Salmonella, Listeria monocytogenes, Staphylococcus aureus, and Bacillus cereus, may induce foodborne diseases causing symptoms such as abdominal pain, diarrhea, nausea, and vomiting. Therefore, microbial control is a critical step in the production of prepared dishes.

In a recent review published in the KeAi journal Food Physics, a team of researchers evaluated microbial control techniques commonly used in prepared dishes.

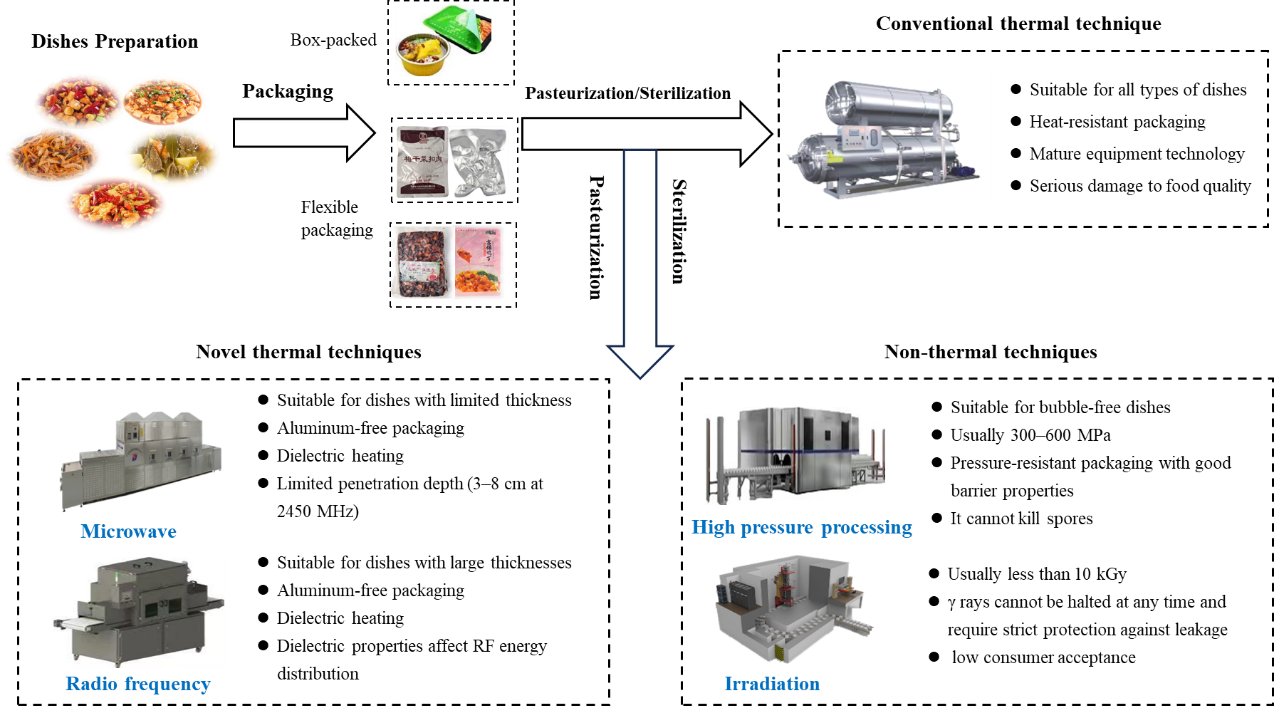

“Commonly used microbial control techniques in industry include conventional thermal technique, microwave (MW), radio frequency (RF), high-pressure processing (HPP) and irradiation,” shares corresponding author of the review. “Conventional thermal technique can be used for all types of prepared dishes but may cause quality degradation. MW has poor penetration ability and is only suitable for treating dishes with moderate thickness. RF is effective for dishes with substantial thickness and regular shape. HPP is not suitable for dishes containing air bubbles, while irradiation is usually used for dishes with low initial microbial load.”

Furthermore, these technologies have different requirements for packaging; conventional thermal techniques need heat-resistant packaging; dishes packaged in aluminum-based materials shielded against electromagnetic waves cannot undergo MW or RF treatment; HPP requires pressure-resistant packaging with good barrier properties; and irradiation treatment imposes no special packaging requirements.

“We concluded that no one technology is perfect and versatile enough to be used across various prepared food categories,” adds Jiao. “We need to select the most suitable microbial control technique based on the characteristics of different prepared dishes. Moving forward, the trend will be to combine and leverage the complementary advantages of various technologies.”

Contact author name, affiliation, email address:

Shunshan Jiao, Shanghai Food Safety and Engineering Technology Research Center, School of Agriculture & Biology, Shanghai Jiao Tong University, Shanghai, China, sjiao@sjtu.edu.cn

Funder:

This study was financially supported by Ningbo Key Research and Development Plan (2023Z122).

Conflict of interest:

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

See the article:

Xiushan, Wang, et al. Research Progress on Microbial Control Techniques of Prepared Dishes. Food Physics (2024): 100015, https://doi.org/10.1016/j.foodp.2024.100015